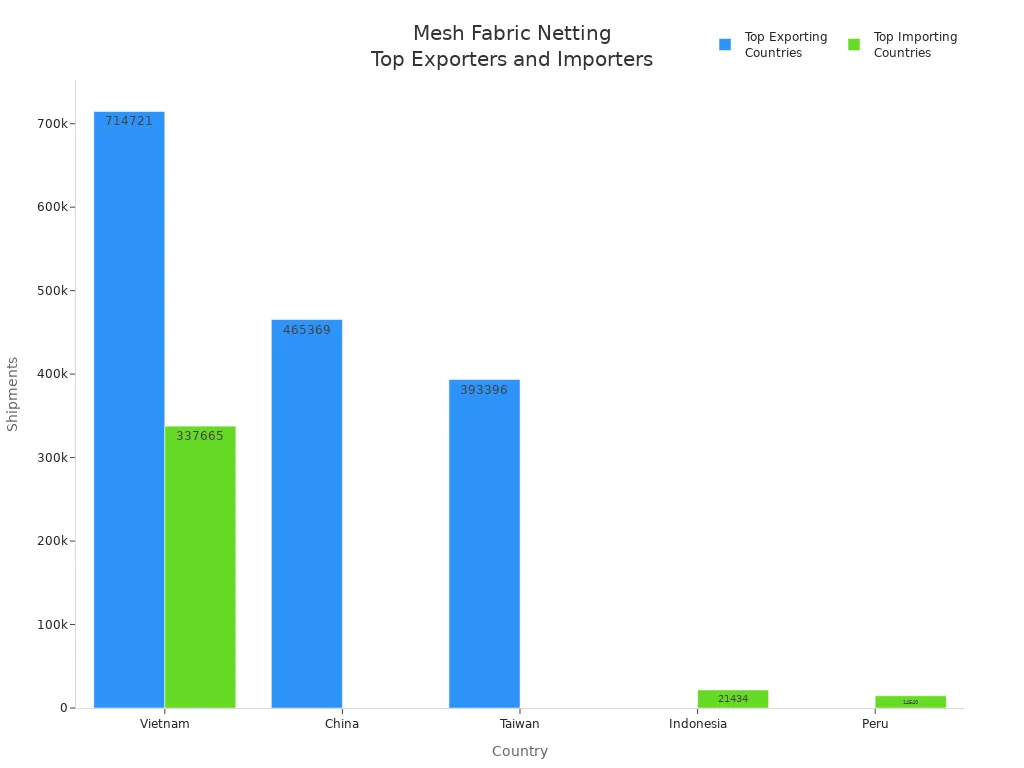

Mesh fabric netting features interconnected fibers that create an open, net-like pattern. This mesh fabric stands out for its lightweight feel, strong durability, and excellent airflow. Many industries choose mesh fabric because it offers breathability, flexibility, and easy care. Manufacturers value its lightweight construction, which supports comfort in clothing and performance in sports gear. The versatility of mesh fabric makes it popular for everything from apparel to industrial uses. Global demand continues to rise, as shown in the table below.

| Metric | Value / Description |

|---|---|

| Total Export Shipments (Nov 2023 – Oct 2024) | 454,161 shipments |

| Export Growth Rate (12 months) | 26% growth compared to previous year |

| Number of Exporters | 15,363 exporters |

| Top Exporting Countries | Vietnam (714,721 shipments), China (465,369), Taiwan (393,396) |

Key Takeaways

- Mesh fabric netting features an open, net-like design that makes it lightweight, breathable, and flexible, ideal for warm weather and active use.

- Nylon and polyester are common fibers in mesh fabric, offering strength, durability, and easy care for sportswear, industrial, and medical products.

- The fabric’s breathability and airflow keep users cool and comfortable, making it perfect for clothing, outdoor gear, and ventilation needs.

- Mesh fabric is durable and easy to maintain; simple washing and gentle care help it last longer and stay fresh.

- Its versatility allows mesh fabric to serve many industries, including fashion, sports, healthcare, automotive, and household items.

Structure and Materials of Mesh Fabric Netting

Open Net-Like Design

Mesh fabric stands out because of its open net-like design. This structure uses interconnected fibers to form uniform holes across the surface. Mesh fabrics often use patterns like open knit or weave, which allow air and light to pass through easily. The open design of mesh fabric improves breathability and ventilation. Many mesh fabrics use patterns such as gauze, grenadine, or marquisette. These patterns help control the size and shape of the holes. For example, gauze uses a leno-weave that keeps the mesh stable and slip-resistant. Mesh fabric with an open structure works well in warm weather clothing, sports gear, and technical uses. The open netting also makes mesh fabrics lightweight and flexible.

Common Fibers Including Nylon Mesh Fabric

Manufacturers often choose fibers like polyester and nylon for mesh fabric. Polyester mesh fabric is popular because it is durable, wrinkle-resistant, and holds color well. Nylon mesh fabric is known for its high strength, elasticity, and chemical resistance. Both polyester mesh fabric and nylon mesh fabric offer excellent breathability and flexibility. Nylon mesh fabric can stretch without losing its shape, making it ideal for sportswear and industrial uses. Polyester mesh fabric is smooth and strong, which helps it last a long time. Some mesh fabrics use cotton, but polyester mesh fabric and nylon mesh fabric are more common because they are more durable and breathable. Nylon mesh fabric is also lightweight and easy to maintain. Polyester mesh fabric provides a good balance of strength and comfort.

| Fiber Type | Key Advantages | Common Uses |

|---|---|---|

| Polyester mesh | Durable, colorfast, wrinkle-resistant | Sportswear, bags, screens |

| Nylon mesh | Strong, elastic, chemical-resistant, breathable | Athletic gear, industrial |

| Cotton mesh | Soft, biodegradable | Some clothing, accessories |

Manufacturing Methods

Mesh fabric can be made using several methods. The most common methods include knitting and weaving. Tricot and Raschel are two popular knitting techniques for mesh fabrics. Tricot mesh fabric uses all knit stitches and can have one to four yarn sets. Raschel mesh fabric forms vertical columns of chain stitches with horizontal yarns. These methods create mesh fabrics with different levels of flexibility and strength. Nets and laces are other types of mesh fabric made by twisting, interlocking, or knitting fibers. The choice of method affects the openness, strength, and flexibility of the mesh fabric. Some mesh fabrics receive special finishes, such as antimicrobial or fire-retardant treatments, to improve performance. Manufacturers select the best method based on the intended use of the mesh fabric, whether for nylon mesh fabric, polyester mesh fabric, or other types.

Key Benefits and Properties of Mesh Fabric Netting

Breathability and Airflow

Mesh fabric netting stands out for its exceptional breathability. The open structure of mesh fabrics allows air to move freely through the material. This feature helps keep users cool and comfortable, especially during physical activity or in hot weather. Mesh fabric supports moisture evaporation, which prevents overheating and sweat buildup.

Laboratory tests show that mesh fabric has much higher air permeability than other textiles. The table below compares air permeability values for different fabrics:

| Fabric Type | Air Permeability (L/m²/s) |

|---|---|

| Mesh Fabric | 500 – 3000 |

| Cotton | 100 – 300 |

| Linen | 200 – 500 |

| Polyester | 50 – 200 |

| Wool | 10 – 150 |

| GORE-TEX | 5 – 15 |

Mesh fabric netting provides the highest breathability, making it ideal for sportswear, summer clothing, and applications where airflow is important. Nylon mesh fabric and polyester mesh fabric both offer excellent ventilation, which helps regulate temperature and comfort. Scientific studies confirm that mesh fabrics allow strong airflow, even in challenging environments like greenhouses and agricultural tunnels. These studies show that mesh fabric netting can control microclimates by letting air pass through while still offering protection.

Note: Mesh fabrics with higher porosity and lower aerodynamic resistance provide better ventilation and airflow, which is important for both clothing and industrial uses.

Lightweight and Flexible

Mesh fabric is known for being both lightweight and flexible. The open net-like design reduces the amount of material used, which makes mesh fabrics easy to carry and wear. Nylon mesh fabric and polyester mesh fabric both contribute to this lightweight quality. People often choose mesh fabric for items that need to be breathable and lightweight, such as athletic shoes, backpacks, and hats.

The flexibility of mesh fabric netting allows it to bend, stretch, and fit different shapes without losing its form. This property makes mesh fabrics suitable for many products. For example, in agriculture, flexible mesh fabric can cover crops and adapt to plant shapes. In construction, mesh fabric fits around scaffolding and provides safety. Automotive interiors use flexible mesh fabric for seat covers that adjust to the body. Nylon mesh fabric is especially valued for its elasticity and ability to return to its original shape after stretching. Polyester mesh fabric also offers flexibility, making it a popular choice for clothing and accessories.

- Mesh fabric netting is:

- Easy to fold and store

- Comfortable to wear

- Adaptable to many shapes and uses

The combination of being breathable and lightweight, along with flexibility, gives mesh fabrics a unique advantage in both fashion and functional products.

Durability and Strength

Durability is a key benefit of mesh fabric netting. Synthetic mesh fabrics, such as nylon mesh fabric and polyester mesh fabric, are more durable than most natural fabrics. These materials resist shrinking, stretching, and wear over time. Nylon mesh fabric is known for its elasticity, wear resistance, and heat tolerance. Polyester mesh fabric is strong, holds its shape, and resists wrinkles.

- Synthetic mesh fabrics:

- Last longer than natural fabrics

- Resist damage from washing and daily use

- Maintain their structure and support

Specialized mesh fabrics, like power mesh, keep their shape and provide support for long periods. Nylon mesh fabric and polyester mesh fabric are easy to maintain and less likely to shrink or wrinkle. Mesh fabric netting is also cost-effective, as it requires less frequent replacement compared to some natural fabrics. The durability of mesh fabrics makes them suitable for demanding uses, such as sports gear, industrial filters, and safety equipment.

Tip: To extend the life of mesh fabric, wash with cold water and avoid harsh chemicals.

Mesh fabric netting combines breathability, lightweight design, flexibility, and durability. These properties make mesh fabrics a top choice for many functional and everyday products.

Easy Maintenance and Cleaning

Mesh fabric netting stands out for its easy maintenance and cleaning. This quality makes it a top choice for many consumer and industrial products. The open structure of mesh fabric allows dirt and debris to pass through, which helps keep the material clean. The lightweight nature of mesh fabric also means that washing and drying take less time and effort.

Many people choose mesh fabric netting because it combines breathability, durability, and lightweight design. These features make cleaning simple and help the fabric last longer. Mesh fabric netting resists stains and odors, which supports its use in sportswear, household items, and packaging. The ease of cleaning also adds to the functional value of mesh fabric in daily life.

Tip: Regular cleaning helps maintain the breathability and durability of mesh fabric netting, ensuring it stays fresh and functional.

Recommended Cleaning and Maintenance Steps

- Wash mesh fabric in cold water by hand or on a gentle machine cycle to extend its lifespan.

- Brush the fabric gently with a soft-bristled brush to remove surface dirt and prevent pilling.

- Pre-treat tough stains with mild solutions like baking soda paste or diluted vinegar.

- Store mesh fabric folded or hung in a cool, dry place away from heat sources.

- Avoid harsh chemicals such as bleach or fabric softeners, as these can damage the fibers.

- Remove stains and dirt promptly to prevent permanent marks.

- Never use petrochemicals or solvents like gasoline or oil on mesh fabrics.

A step-by-step approach helps keep mesh fabric netting in top condition:

1. Preparation: Check for stains or dirt. Remove surface stains with a soft brush or damp cloth. Always read the care label for specific instructions. 2. Detergent choice: Use neutral detergents. This protects the fiber structure and prevents deformation, fading, or reduced durability. 3. Washing methods: Hand wash in warm water with gentle rubbing. Machine wash on a gentle cycle using a laundry bag to avoid damage. 4. Drying: Lay flat in a ventilated area away from direct sunlight or high heat. Use a towel to absorb excess water if needed. 5. Maintenance: Avoid long exposure to sunlight to prevent fading and aging. Keep mesh fabric away from sharp objects to avoid fiber damage. Clean regularly based on use and stains. Use insect repellent when storing for long periods. Store in dry, ventilated places away from moisture, mold, chemicals, and harmful gases.

The lightweight and breathable qualities of mesh fabric netting make these steps easy to follow. Quick drying and simple washing routines save time and energy. These benefits support the use of mesh fabric in products that require frequent cleaning, such as athletic gear, backpacks, and household organizers.

Manufacturers and consumers both value the durability and functional advantages of mesh fabric netting. Its easy maintenance supports sustainability and user convenience. Many industries rely on mesh fabric for its lightweight feel, breathability, and long-lasting performance.

Applications of Mesh Fabrics Across Industries

Apparel and Fashion (e.g., sportswear, Suerte, lingerie)

Mesh fabric plays a vital role in the apparel and fashion industry. Designers use mesh fabrics in sportswear, activewear, and lingerie because of their breathability and comfort. Polyester mesh fabric is especially popular in sportswear, as it allows air to flow freely and wicks moisture away from the skin. This helps athletes stay cool and dry during intense activities. Mesh panels and laser-cut details add style and improve ventilation in activewear. Many brands, including Suerte, use mesh fabrics for shaping and body contouring in fashion pieces. Mesh fabrics also provide durability and a lightweight feel, making them ideal for everyday wear. The variety of applications in fashion highlights the versatility of mesh fabric.

- Mesh fabric in sportswear and activewear:

- Enhances breathability and comfort

- Wicks moisture for cool, dry performance

- Adds style with mesh panels and details

- Supports body contouring and shaping

Sports and Outdoor Gear (e.g., athletic shoes, backpacks, tents)

Mesh fabrics are essential in sports and outdoor gear. Manufacturers use mesh fabric in athletic shoes, backpacks, and tents to improve airflow and reduce weight. The open-weave structure of mesh fabrics keeps users cool and dry by allowing air to circulate and moisture to escape. Mesh fabric is durable and withstands heavy use and extreme weather, making it perfect for outdoor gear. Flexible mesh adapts to body movements, providing comfort and an ergonomic fit. Quick-drying and UV-resistant treatments extend the life of outdoor products. Mesh fabrics appear in a wide range of applications, from clothing and footwear to tents and accessories, supporting comfort and performance in outdoor environments.

Tip: Mesh fabric in outdoor gear helps users stay active longer by reducing fatigue and improving ventilation.

Industrial and Commercial Uses (e.g., filtration, packaging, safety gear)

Mesh fabrics serve many industrial applications. In construction and manufacturing, handwoven stainless steel mesh provides protective netting for scaffolding barriers, debris containment, and machinery guarding. These uses require mesh fabrics with high tensile strength, corrosion resistance, and compliance with safety standards. Mesh fabric is lightweight yet strong, making installation easy while maintaining safety. In occupational safety, mesh fabrics appear in safety harnesses, high-visibility vests, and cut-resistant garments. The healthcare industry uses mesh fabrics for patient lift slings, mesh curtains, and orthopedic braces. Filtration systems rely on mesh fabric for dust collection, fuel filtration, and medical filters. Mesh fabrics also support packaging and protective netting in shipping and storage.

| Industry/Application | Common Uses/Products | Performance Criteria |

|---|---|---|

| Recreation | Sports nets, camping gear, pool nets | Durability, mildew resistance |

| Occupational Safety | Safety harnesses, vests, cut-resistant garments | Tensile strength, compliance |

| Automotive/Marine | Seat pockets, safety harnesses, cargo nets | UV and moisture resistance |

| Healthcare | Patient slings, mesh curtains, braces | Antimicrobial, comfort |

| Filtration | Dust, oil, lab filters | Aperture size, chemical resistance |

Mesh fabrics meet strict requirements for safety, durability, and performance, making them indispensable in a variety of applications.

Medical and Healthcare (e.g., bandages, support braces, surgical mesh)

Mesh fabric plays a vital role in medical applications. Hospitals and clinics use mesh fabrics in bandages, support braces, and surgical mesh. These products rely on the unique properties of mesh fabric, such as breathability, flexibility, and strength. Mesh fabrics allow air to reach wounds, which helps healing and reduces moisture buildup. Support braces made from mesh fabric provide stability while letting skin breathe.

Surgical mesh stands out as a key medical application. Doctors use synthetic mesh fabrics like polypropylene, polyester, and ePTFE for hernia repairs and other surgeries. Polypropylene mesh contracts 30-50% after placement, which can cause complications. Polyester mesh shows better tissue incorporation in animal studies, while ePTFE mesh reduces adhesions but may have higher recurrence rates. Absorbable mesh fabrics, such as Dexon and Vicryl, serve as temporary barriers and dissolve over time. Biological mesh fabrics, made from processed tissues, support tissue remodeling and lower infection risks. Clinical studies show that biological mesh fabrics perform better in contaminated surgical fields and resist infection more than synthetic options. The integration process involves inflammation, cell growth, and new tissue formation. Mesh fabrics in medical applications offer a wide range of benefits and support a variety of end uses.

Note: More clinical trials are needed to confirm the long-term safety and effectiveness of different mesh fabrics in medical applications.

Household and Everyday Items (e.g., laundry bags, window screens, organizers)

Mesh fabric appears in many household products. People use mesh fabrics for laundry bags, window screens, and organizers. Mesh fabric in curtains and drapes creates a light, airy look while allowing sunlight to enter and keeping privacy. Table linens and runners made from mesh fabric add texture and style to dining areas. Cushion covers and throws use mesh fabrics for a modern, breathable touch.

Consumers value mesh fabric for its lightweight feel and breathability. Mesh fabrics improve airflow and comfort in homes. The material offers durability, even though it feels light. Mesh fabrics also make crafting and DIY projects easier because they are easy to handle. The wide range of applications in the home shows how mesh fabric meets many needs.

- Common household uses for mesh fabric:

- Laundry bags

- Window screens

- Table linens

- Cushion covers

- Organizers

Automotive and Transportation (e.g., seat covers, cargo nets, sunshades)

Mesh fabric supports many automotive and transportation needs. Car manufacturers use mesh fabrics for seat covers, which keep seats cool and comfortable. Mesh fabric in cargo nets helps secure items during travel. Sunshades made from mesh fabric block sunlight while letting air flow through the vehicle.

Mesh fabrics in vehicles must be strong and durable. The open structure of mesh fabric allows for ventilation, which prevents heat buildup inside cars and trucks. Mesh fabrics also resist wear and tear, making them ideal for daily use in transportation. The variety of end uses in this sector highlights the adaptability of mesh fabric. Mesh fabrics meet the demands of both comfort and function in automotive and transportation products.

Why Mesh Fabric Netting Is So Popular: Benefits and Uses

Meeting Modern Needs

Mesh fabric netting continues to gain popularity because it meets the changing needs of modern life. People want clothing and products that offer comfort, style, and function. Mesh fabrics deliver these qualities through breathability and moisture-wicking properties. The athleisure trend has increased demand for mesh fabric in sportswear and casual wear. Many brands now use recycled polyester and organic fibers, reflecting a shift toward sustainability. Mesh fabrics also support active lifestyles by providing lightweight comfort and quick-drying features. Innovations such as antimicrobial and UV-resistant finishes improve performance for outdoor and safety uses. Mesh fabric netting adapts to new trends, making it a top choice for both consumers and manufacturers.

| Industry/Application | Demand Drivers and Trends | Regional Growth Drivers |

|---|---|---|

| Textile | Fashion trends, custom printing, e-commerce growth | Asia Pacific and North America: industrialization, consumer awareness |

| Electronics | Use in PCBs and components, demand for precision and innovation | Asia Pacific and North America: advanced manufacturing capabilities |

| Automotive | Filtration systems, electronic components, shift to electric/hybrid vehicles | North America and Asia Pacific: automotive innovation and sustainability focus |

| Mining | Durable materials for grading and filtering, expansion of mining activities | Asia Pacific: resource-rich regions and sustainable mining practices |

| Construction & Agriculture | Reinforcement, pest barriers, crop protection | Growing construction and agricultural sectors globally |

| Emerging Industries | Renewable energy (solar, wind), biotechnology filtration | New growth areas expanding mesh fabric applications |

Adaptability Across Industries

Mesh fabrics show remarkable versatility. Different industries modify mesh fabric by changing fiber types, thickness, and pore size. For example, sportswear brands select mesh fabrics with high breathability and stretch for activewear. The automotive industry uses mesh fabric for seat covers and filtration systems. Medical fields rely on mesh fabrics for bandages and support braces. Industrial sectors customize mesh fabric for filtration, packaging, and safety gear. Companies can slit, cut, or fabricate mesh fabric into components like filter cores and protective sleeves. This adaptability allows mesh fabrics to meet specific needs in outdoor, safety, and technical applications.

- Mesh fabric modifications include:

- Adjusting pore size for filtration

- Selecting fibers for durability or flexibility

- Creating custom shapes for industrial uses

Cost-Effectiveness and Accessibility

Manufacturers and consumers choose mesh fabric for its cost-effectiveness and wide range of uses. Mesh fabrics are lightweight, which reduces shipping and production costs. The durability of mesh fabric means products last longer and require less frequent replacement. Mesh fabrics resist wear and tear, making them ideal for high-energy activities and safety equipment. The open structure allows for easy cleaning and maintenance, saving time and resources. Mesh fabric netting is accessible in many markets due to its simple production process and the availability of synthetic fibers. Its versatility and functional benefits make mesh fabric a practical solution for outdoor gear, safety products, and everyday items.

Mesh fabric netting stands out for its breathability, lightweight feel, and versatility, making it a preferred material across many industries.

Mesh fabric stands out for versatility, durability, and comfort. Case studies show mesh fabrics excel in animal enclosures, outdoor furniture, and gear, offering strength and adaptability. Mesh fabrics provide breathability, flexibility, and easy maintenance, making them practical for sportswear, industrial products, and medical devices. Recent innovations include 3D spacer mesh fabrics for automotive and medical uses. Mesh fabric continues to deliver practical solutions for many industries. Suerte products highlight how mesh fabrics meet modern needs with quality and innovation.

FAQ

What is mesh fabric netting used for?

Mesh fabric netting appears in sportswear, outdoor gear, medical products, and household items. Many industries choose mesh fabric for its breathability, lightweight feel, and durability.

How do you clean mesh fabric netting?

Hand wash mesh fabric in cold water with mild detergent. Use a gentle brush for stains. Air dry the fabric away from direct sunlight. Avoid bleach and harsh chemicals.

Is mesh fabric netting strong?

Mesh fabric netting made from nylon or polyester offers high strength and durability. It resists stretching, tearing, and daily wear. Many industries use it for safety gear and industrial applications.

Can mesh fabric netting be customized?

Manufacturers can customize mesh fabric netting by changing fiber type, color, pattern, and pore size. Suerte Textile offers design support and quick sample verification for custom orders.

Why does mesh fabric netting dry quickly?

The open structure of mesh fabric allows air to flow freely. This design helps moisture evaporate faster than in solid fabrics. Quick drying makes mesh fabric ideal for sportswear and outdoor products.